|

| November 22, 2016 | Volume 12 Issue 44 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Stratasys and Siemens partner to incorporate additive manufacturing into volume production

Stratasys and Siemens have announced a formal partnership to integrate Siemens' Digital Factory solutions with Stratasys' additive manufacturing solutions.

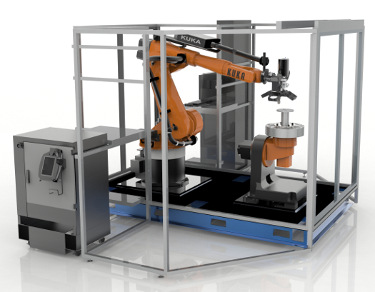

Stratasys Robotic Composite 3D Demonstrator presents a hybrid approach to automated composite part production, incorporating 3D printing, subtractive manufacturing (machining), inspection, and product finishing in a single work cell. [Photo: Stratasys]

The partnership is intended to lay the foundation for the two companies to fulfill a shared vision of incorporating additive manufacturing into the traditional manufacturing workflow, helping it to become a universally recognized production practice that can benefit multiple industries, including aerospace, automotive, transportation, energy, and industrial tooling. This announcement also builds on Siemens' recently announced end-to-end solution integrating digital design, simulation, and data management with conventional and additive manufacturing.

Stratasys and Siemens have been collaborating on multiple projects, including the direct link from Siemens' NX software for CAD/CAM/CAE to Stratasys' GrabCAD Print platform (enabling a seamless design-to-3D-print workflow) and the recently previewed Stratasys Robotic Composite 3D Demonstrator that incorporates Siemens' product lifecycle management (PLM) software and its motion control and CNC automation technologies to produce strong, lightweight performance parts.

While additive manufacturing technology has made great strides over the past years, additional criteria are required for it to take its place in volume production environments and become as commonplace as CNC.

Ideally, additive manufacturing solutions should deliver robust, repeatable, and reliable operational performance with predictable properties across a broad portfolio of materials that are certifiable for specific applications. These processes should be driven by a seamless, digital integration from design to production. Together, Stratasys and Siemens plan to address these challenges.

Stratasys and Siemens showcased their next-generation additive manufacturing solutions at the formnext 2016 exhibition in Frankfurt on Nov. 15-18. Stratasys' Robotic Composite 3D Demonstrator was featured in a unique virtual 3D-printing experience. In addition, Siemens demonstrated its end-to-end additive manufacturing software solution along with its scalable hardware platform for motion control and relevant manufacturing processes.

At the core of the 3D Demonstrator is Stratasys' advanced FDM (Fused Deposition Modeling) Additive Manufacturing technology synchronized to complex multi-axis motion. It features Stratasys' extensible and scalable multi-operation architecture that provides the flexibility to integrate subtractive manufacturing, inline inspection, and verification and product finishing. Stratasys engineered materials are employed to produce structures that are optimized for weight and performance. The result is a new hybrid manufacturing approach that is unconstrained by the traditional limitations of composite lay-up and the layer-by-layer limitations and support material requirements of traditional 3D printing.

The new workflow for the Stratasys Robotic Composite 3D Demonstrator begins with Siemens' NX software. NX enables designers to create parts to be produced on the system, simulate and evaluate the design for manufacturability, and generate and send all the manufacturing instructions for part production. Throughout the manufacturing process, performance is controlled and communicated directly to the manufacturing operations management systems. The result is a seamless CAD-to-product workflow that streamlines production and ensures end-to-end traceability and part quality.

The motion control for the Stratasys Robotic Composite 3D Demonstrator is driven by the Siemens' Sinumerik 840D sl CNC. The open architecture of Sinumerik control combines the strengths of Siemens' NC with flexible robot kinematics. The integration with Stratasys' extrusion control technologies to execute manufacturing instructions from NX CAM results in a high degree of freedom for robotic FDM extrusion.

Siemens Digital Factory offers a comprehensive portfolio of seamlessly integrated hardware, software, and technology-based services in order to support manufacturing companies worldwide in enhancing the flexibility and efficiency of their manufacturing processes and reducing the time to market of their products.

Source: Stratasys

Published November 2016

Rate this article

View our terms of use and privacy policy